Engineers and manufacturers require high-end accuracy and efficiency to produce reliable, high-end product outcomes. Using ETA Dynaform 7.1 as the serving software instrument for the production sector for sheet metal forming proves to be very beneficial. Engineering professionals use this advanced software to perform virtual analyses of sheet metal formation and optimize the process, saving production expenses and time. This technology gives users virtual environments that help them detect possible issues before design completion through data-based decision-making. Getitinpc.com provides users with easy downloads.

Overview of ETA Dynaform 7.1

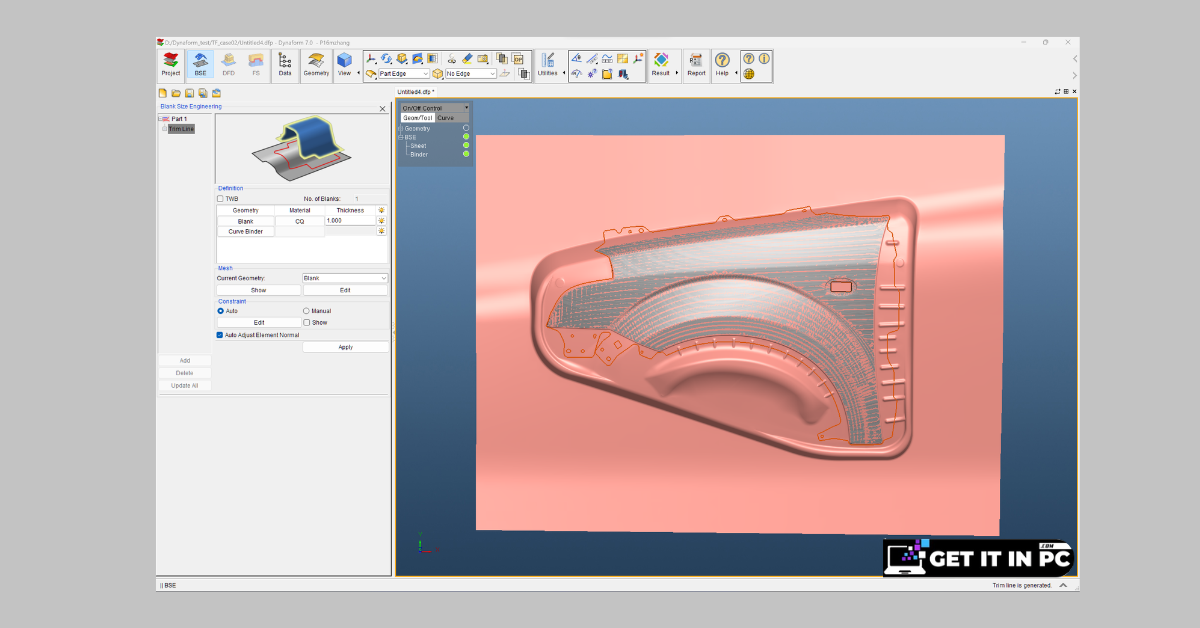

All sorts of tools in the ETA Dynaform permit simulation and analysis of sheet metal forming. Engineers use this system to manipulate metal components before production, reducing errors and saving on the material. As it stands, ETA Dynaform 7.1 offers a complete deep overview of stamping bending and deep drawing forming of metal operations that aid in the quality and performance level increase in metal products. This software is leveraged by the consumer goods industry and the automotive and aerospace sectors to minimize the costs of resources while enhancing production efficacy.

With ETA Dynaform, material mechanics can be examined throughout the forming operations, design mechanics and machine instrumentality are tested, and material characteristics are evaluated. This software allows manufacturers to pinpoint possible material cracks and thin areas during product design, modifying their designs before making costly physical prototypes. It features an entire procedure with high accuracy, reliability, and associated cost savings. The newest version of ETA Dynaform 7.1 provides powerful tool capabilities and allows users to access Getitinpc.com.

Click here to install 3DCS Variation Analyst 8.0.0.0 – Free Download

Key Features

- The precision of simulation of sheet metal forming procedures such as deep drawing and stamping and bending operations is provided by ETA Dynaform.

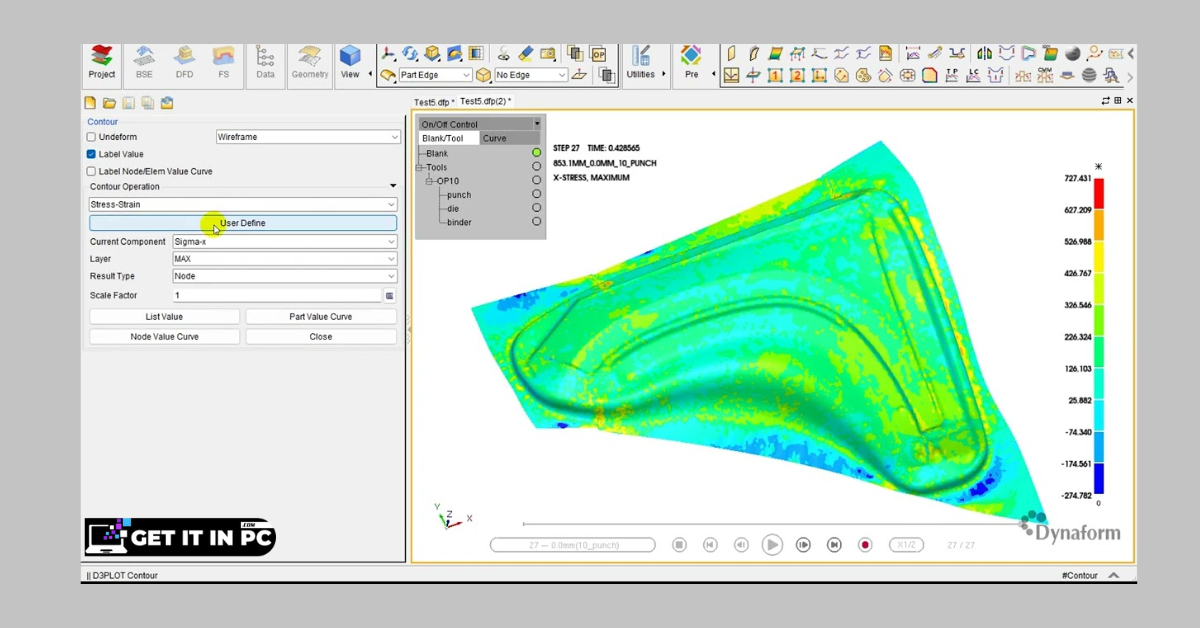

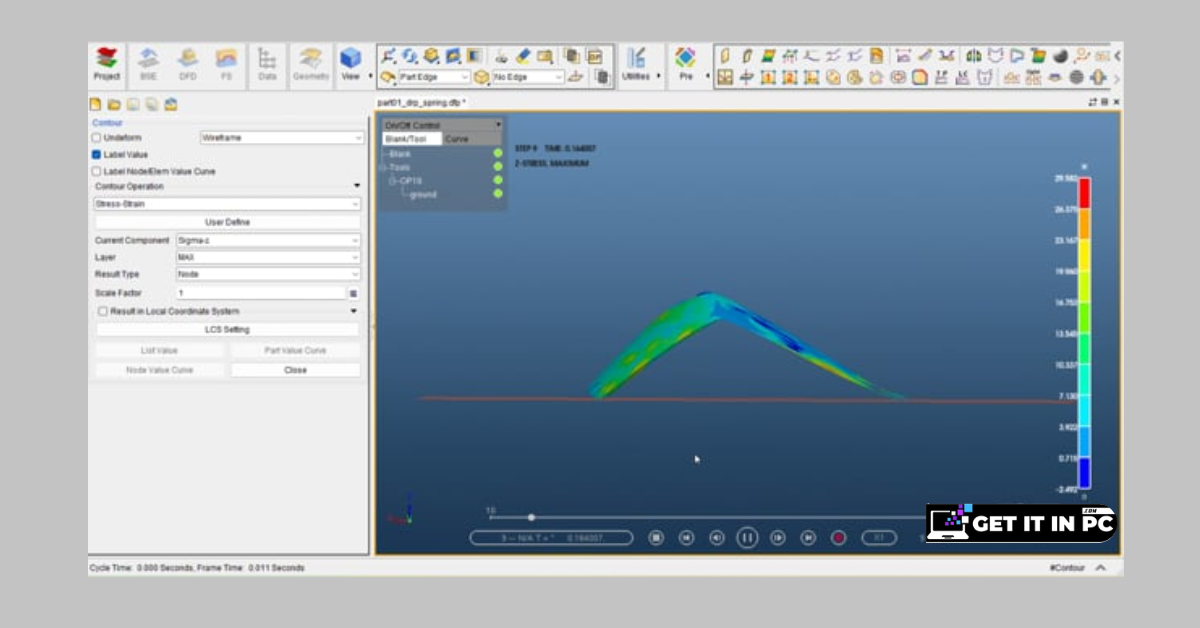

- Through Material Behavior Analysis, the mechanical properties and material behaviour of processed materials should be evaluated.

- Forming limit diagrams (FLD) should be generated to identify the sections most likely to fail during the forming process.

- Researchers can evaluate the effects of tool geometry on improving tool performance through die design optimization.

- Blank Size Optimization generates automatically optimized blank shapes, which minimize material waste using the optimization process.

- Now, the system detects upcoming failure patterns, such as wrinkles, tears, and material thinning, and modifies itself as needed to avoid them.

- Modern meshing methods allow engineers to model precise high-resolution models of the forming procedure.

- The platform’s interface is user-friendly, with a simple design that makes it easy for the user to reach results quickly when navigating through them.

- The interface allows users to link the program to many CAD tools for an improved workflow.

- The system automatically creates vast volumes of reports on simulation outputs, improving the clarity of findings.

- The users can save on physical testing expenses and obtain better results through virtual prototyping.

- The program allows users to generate a complete material database, which allows them to predict the behavior of different metals and alloys.

- The user addresses each manufacturing operation by defining their processing parameters, including tool speeds, forces, and temperature settings.

- This allows the system to detect process-related errors and perform automatic correction sequences to maintain operational excellence.

- Automatic data exchange between manufacturing systems and ETA Dynaform 7.1 software enables automatic information time between simulation operations and production activities.

Download detailed details about ETA Dynaform 7.1 software capabilities at Getitinpc.com.

System Requirements for ETA Dynaform 7.1

Before installing ETA Dynaform, it is necessary to verify the system requirements for the ETA Dynaform 7.1 to function optimally. Here are the system requirements:

- Operating System: Windows 10 (64-bit) or later.

- Processor: Intel Core i5 or higher.

- RAM: 8 GB minimum (16 GB recommended).

- Disk Space: 10 GB of free disk space for installation.

- This software needs an OpenGL-supporting graphics card from either NVIDIA or AMD.

- It is necessary to connect to the internet for software update functions, and an internet connection is also needed to activate it.

Downloading Setup

The installation of ETA Dynaform is based on a standard procedure. This procedure leads to downloading the software, which is obtained through Getitinpc.com.

- To find ETA Dynaform 7.1 using Getitinpc.com, you can use proper keywords in the search field of the search function.

- By default, you should be able to find the software download link to proceed.

- First, double-click the setup file you downloaded to begin setup installation.

- Users will see the installation guide on the screen, and everything should be done accordingly.

- ETA Dynaform is provided as soon as you start using it to optimize and simulate your sheet metal forming operations after the installation.

Getitinpc.com provided detailed instructions regarding the software’s usage and made it available for download.

Free Download Button

Obtain the cost-free download of ETA Dynaform 7.1 from Getitinpc.com. The software is used as a simulation tool of sheet metal forming to assist you in manufacturing operations, and design efficiency cuts down on material losses. To download ETA Dynaform, users can click the button below to access the complete activated version. Don’t wait to take advantage of this opportunity to enhance your production process while increasing productivity.